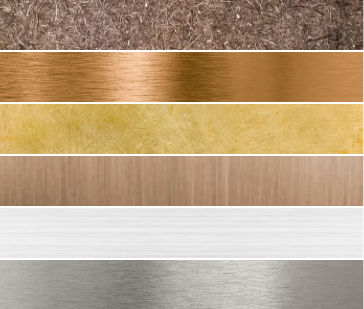

Tin Bronze

Better corrosion resistance than the tin bronzes with low tin content. Higher strength and very good sliding properties, good cold formability, easily soluble. Sliding elements, sliding bearings (in particular thin-walled) and sliding guides. Highly stressed worm wheels and gears, bolts and screws.

Gunmetal Tin Bronze

Hard tin bronze with high wear resistance and good emergency running properties. More difficult to machine than leaded tin bronze. Due to the high hardness and wear resistance, surface-hardened shafts are recommended and the highest surface quality is required. Edge pressing must be avoided. Corrosion and seawater resistant.

Aluminium Bronze

Construction material with high strength values, resistant in cold and even hot sea water. Very good heat resistance. Very good fatigue strength in air and seawater. Very good cavitation and corrosion resistance, highly resilient with good wear resistance. Good lubrication required for sliding loads. Very good pressure tighness. Very easy to weld. Highly stressed slide bearings and worm rims. Worm and helical gears at the highest tooth pressures. Superheated steam fittings, fittings for aggressive waters, water pump housing, chemical industry, shipbuilding.

Special Brass

Construction material with high strength. Good resistance against atmospheric corrosion, slightly aggresive water and also against gases and oil corrosion. For high demands on sliding loads, high wear resistance. Medium machinability. Structural parts in mechanical engineering, plain bearing, valve guide, gear parts and piston rings.