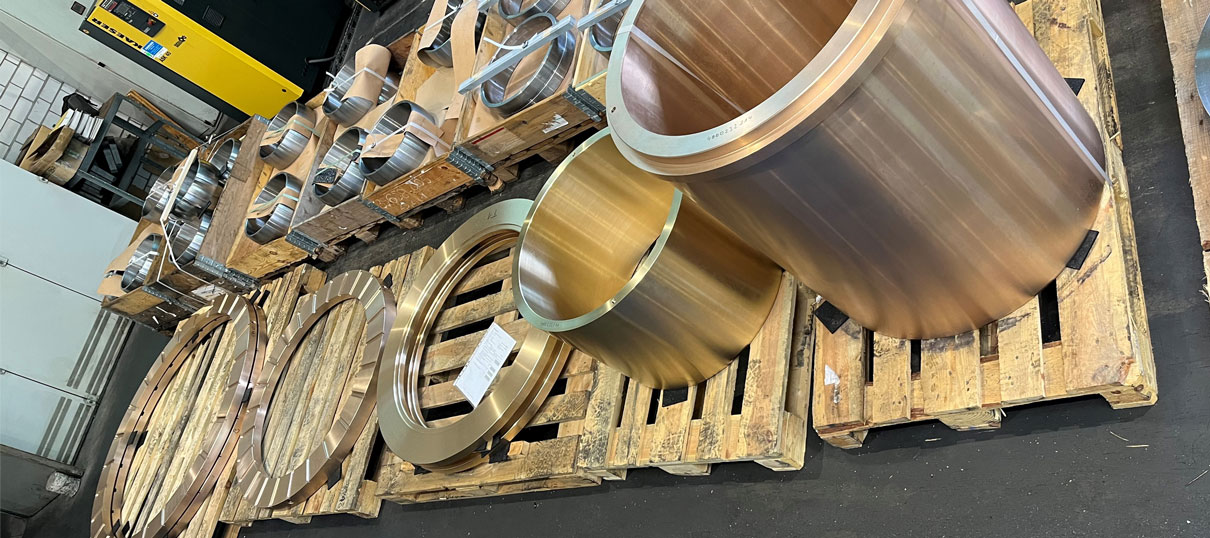

SUPPLY OF SPARE PARTS FOR CRUSHER

Bornebusch is the spezialist for crusher spare parts in bronze. Pre-Machines und Finish-Machined. All spare parts for rock crushing machines are manufactured at Bornebusch using the centrifugal casting process. Through this rotational technique, components such as eccentrics, liners, and bearings are produced in a wide range of sizes. By precisely controlling the quantity of molten metal and utilizing centrifugal force, this method eliminates the need for internal cores, resulting in a uniform material composition.