Automation in manufacturing for fast delivery requirements

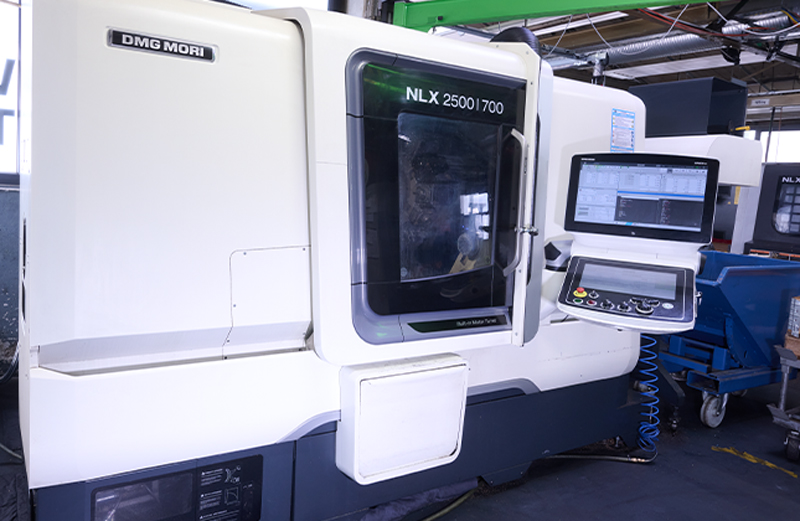

We continuously invest in the latest (CNC) machines to implement your projects efficiently and precisely. Thanks to our modern equipment, we can reliably handle your orders — often even at short notice — while guaranteeing the highest quality. With state-of-the-art technology, we work faster and more accurately, increasing productivity and ensuring results that fully satisfy our customers. We machine all common materials (steel, plastics, non-ferrous metals, etc.).

Ideally suited for the production of:

- Flanges

- Long-turned parts

- Camshafts

- Shafts

- Sprockets

In addition to optimized product quality, our machines also allow us to respond flexibly to individual customer requirements.Furthermore, newly installed photovoltaic systems supply our operations with green energy, making our production process even more sustainable.

BENEFITS

- Shortest set-up times thanks to automatic tool change

- B axis with + -120 ° swivel angle and 0.001° resolution

- Minimized downtime due to multitools and sister tools

- Highest positioning accuracy and performance thanks to integrated spindle drives up to 5,000 rpm and 345 Nm, and integrated C axis (0.001°)

- No driven tool holder necessary

- Generous work space for components of up to Ø400mm x 1,100 mm

- Multijob: No tool setup when producing different workpieces

![[Translate to English:] Application examples, Chain wheel](/fileadmin/user_upload/AdobeStock_800368778.jpg)

![[Translate to English:] Application examples, Flange](/fileadmin/user_upload/AdobeStock_53427587.jpg)

![[Translate to English:] Application examples, Cam shaft](/fileadmin/user_upload/Nockenwelle-2.jpg)